SC TEHNOUTILAJ SA Husi started its activity on 28th November 1998, initially being organized as a “company with limited responsibility” and having as main object of activity the retail trade of “all products and repair parts used in industry”.

Afterwards, it became a “stock corporation” by increasing its social capital and cooptation of new associates, starting with April 27th 1999. From that moment on, the company has diversified its activity, manufacturing products and offering services for the oil, metallurgical and alimentary fields.

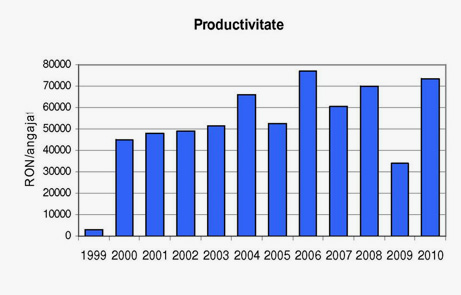

Since January 2000, the production of repair parts and services for oil and metallurgical equipment has represented the main share in the production activity. The company has recorded distinguished results in the export of repair parts for oil and alimentary equipment by means of some export trade companies („Industrialexport” and „Gazteh” Bucharest). The increasing continuous trend of its activity has also facilitated the development of the activity by acquiring a production assembly-room and an important number of equipment – a situation which has implicitly led to employing specialized trained workforce.

In 2004 TEHNOUTILAJ signed an investment program, RICOP 1, with self contribution and PHARE, with the aim to enlarge the production space and to build an administrative building, as well as to purchase new equipment in order to diversify the product range. At present, the social capital of the company is up to 1, 5 billion lei. .

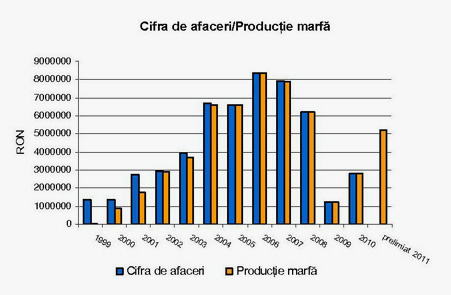

Capital is 100% private company, the shareholder structure is comprised of individuals who are Romanian citizens. Turnover for 2010 was 2.786 million lei. It has achieved a net profit of 15,144 lei.

The company has 120 employees who deploy their activity within the production department structured as it follows:

- two machining assembly rooms (mechanic machining)

- an assembly room for metallic garment

- an assembly room for thermal treatments

- the vulcanization sector

- dynamic balancing

At the same time with the efforts made for technologizing the company, a special attention is paid for the continuous improvement of the qualification level of the employees and for keeping them within the company by improving the working conditions.

Within the directorate board, there are specialists with great experience in management and a strong technical expertise.

The administrator, Mrs. Ing. Nicoleta ROTARIU, has an experience of over twenty years in the specific industry, both in production and in leadership jobs. During 1984-1996 she functioned as Chief for the department for Work Management/ Standardization and as Chief for the Provision – Marketing – Export Department at SC PETAL SA.; during 1996-1998 (when she was the executive manager at S.C. MARSEMAR S.A. Husi) she also specialized in the management and coordination of a company.

The administrator, Mrs. Ing. Nicoleta ROTARIU, has an experience of over twenty years in the specific industry, both in production and in leadership jobs. During 1984-1996 she functioned as Chief for the department for Work Management/ Standardization and as Chief for the Provision – Marketing – Export Department at SC PETAL SA.; during 1996-1998 (when she was the executive manager at S.C. MARSEMAR S.A. Husi) she also specialized in the management and coordination of a company.

Strong points:

- experience in production;

- experience in management;

- entrepreneur skills.

The general attributions of the general manager consist in elaborating the strategies and policies of the company, in the coordination and control of the activities.

The general attributions of the general manager consist in elaborating the strategies and policies of the company, in the coordination and control of the activities. All the production facilities are found in one location, 108 Calea Basarabiei Street, which has ensured the possibility of an optimal technologic management.

The equipment meant for machining covers the entire range of mechanical processing necessary to manufacture the products found in the portfolio – turning, milling, toothing, adjustment etc.

The modern equipment – conversion unit with plasma, continuous welding units in controlled atmosphere – ensures performance in the field of metallic garments.

The thermal treatments made within the company cover the requests for the manufactured products. We have the technological ability for treatments in artificial atmosphere, superficial CIF quenching etc. The vulcanization sector offers the possibility to ensure some important part from the necessary of the products made of rubber included in the supplied products.